| Valve type | ESR High Pressure PRV | ESS High Pressure Cast PRV |

| Common design features High quality steel body for total integrity of pressure containing parts“ Smooth” body contour resists thermal fatigueEasy access to internal parts reduces maintenance costs and system downtimeValve inlet and outlet connections Adaptable to all pipe diameters Advanced seat design assures no energy loss in stand-by conditionSplit pressures class inlet/outlet to minimize thermal stress levels |  |  |

| Application | Controlled pressure relief Process steam Turbine bypass | Controlled pressure relief Process steam Turbine bypass |

| Body style | Angle Fully machined | Globe Fabricated |

| Body material | Forged CrMo-low alloy or carbon steel Optional 13% Cr-steel,F91 | CrMo-low alloy or carbon steel |

| Pressure class, inlet Pressure class, outlet | ANSI # 600-2500,Option # 4500 ANSI# 150-1500 | ANSI # 600-2500 ANSI# 150-1500 |

| Max capacity, Kv (Cv) | 4000 (4680) | 4000 (4680) |

| Leakage class | III-V | III-V |

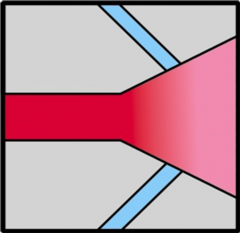

| Plug design available | Cage Balanced Balanced tight Unbalanced | Cage Balanced Balanced tight Unbalanced |

| Special design features | Cage trim with diffusers for low noise and vibration under severe conditions | Standardized cast body design with flanged or butt weld end connections means low investment and installation costs Outlet connection larger than inlet to allow for high pressure ratio |